I had a very interesting debate on FaceBook over this. So I thought it worthy of a blog post.

[Update: Whilst I don't think this is in any way a grey area, the new Highway Code rules from Jan 2022 make this way more clear with rules about giving way entering or leaving a side road when someone is crossing, or waiting to cross]

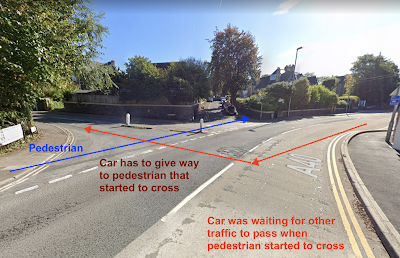

This is a junction in Abergavenny that I walk across every day on my way to town. I walk both ways, but frequently (maybe once a week) someone turning in to the side road will drive at me whilst I am crossing. They are usually not in sight when I started to cross, sometimes they are and waiting on traffic when I start to cross. But the rules are really clear, if I have started to cross then they have to give way to me. Oddly, even though I have no trouble with zebra crossings (everyone is really polite and stops even if I have not started to cross), they get annoyed that they have to stop for me, for some reason. Some very annoyed, stopping, getting out of the car, shouting, etc. It is crazy!

Just to be clear, I also have a lot of cases of drivers being sensible, waiting for me to cross, no annoyance, very civil and safe. Thank you - most of the people of Abergavenny are very civil and polite.

The debate came up because of the "island" in the road. This was not something I had considered an issue. Walking in direction shown, I am crossing a road, and get to the island in the "middle", and a car approaching expects me to stop for some reason. The question being should I stop? or should I expect them to give way as I started to cross the road some time before and am still crossing, so I have priority. To be clear, I always try to make eye contact and try to avoid getting run over (so far with success) - I even wear hi-vis on many occasions.

What are the rules?

The rules are all in the Highway Code, and even though many of these are just advice, and recommendations, and even some that are clear rules are not "laws", they do define how we all use the road together and if followed they help ensure things work smoothly. At the end of the day, the rules can say which of us was right and which was wrong in a case such as this where the car driver has to stop for a pedestrian that is crossing.

- Rule 170: "watch out for pedestrians crossing a road into which you are turning. If they have started to cross they have priority, so give way"

- Rule 8: "At a junction. When crossing the road, look out for traffic turning into the road, especially from behind you. If you have started crossing and traffic wants to turn into the road, you have priority and they should give way (see Rule 170)."

So that is pretty clear, both for a driver and a pedestrian, if you have started to cross (just like a zebra crossing) cars have to give way.

So where does the island come in?

The confusion comes about because of rule 20: "Where there is an island in the middle of a zebra crossing, wait on the island and follow Rule 19 before you cross the second half of the road – it is a separate crossing."

This makes it clear that where there is an island in a zebra crossing, each half of the road is a "separate crossing". So "starting to cross" the crossing (not the road) is not automatically priority over cars for the other "crossing" on the other half of the road.

However, rule 30 is not the same: "Where there are no controlled crossing points available it is advisable to cross where there is an island in the middle of the road. Use the Green Cross Code (see Rule 7) to cross to the island and then stop and use it again to cross the second half of the road."

Both rules make it clear that the road may have two halves, but unlike rule 20, this rule does not say that makes it two separate "crossings" or "roads". Rules 8 and 170 talk of having priority once you have started to cross "the road" or "a road", not "a half of a road" or "a part of a road" or even a "crossing".

So, to me, rule 30 actually clarifies the this is not like a zebra crossing, it is one road, and starting to cross it at all gives the pedestrian priority. As such, when getting to the middle of the road, island or not, they still have priority, and so can reasonably expect the cars turning in to the road to give way as required by rule 170.

The island makes no difference in a side road, even though it does for a zebra crossing. Otherwise the rules are almost the same. Notably a zebra crossing would have a much more serious "island" with the orange globe lights in the middle of the road. For a side road it can be little more that something to support a keep left sign, such as the above. So sort of makes sense.

Just to be clear, the same problem happens when going the other way, where the island is not relevant, and on side roads with no island, but they are not used as much and hence it is much rarer.

Why are people even mentioning the island?

I was also surprised that the whole issue of the island came up. I think people are reading rule 30 and saying that because the pedestrian crosses to the island, stops, and then crosses to the other side of the road, the stopping means they have stopped crossing the road, and start again afterwards, so while stopped they don't have priority. I think that is what people are saying. That may have some validity.

But even if that is how rule 30 can be read, the second someone takes a step from the island they have priority anyway, so in practice cars have to expect to have to give way.

Also, rule 30 is "advice" to pedestrians only. If a pedestrian does not take the advice and crosses where there is no island, and so does not "stop", then the priority clearly starts when they start crossing (the first half of) the road all the way to the other side. Again, cars have to expect to give way to the pedestrian.

Similarly if they decide to only take part of the "advice", cross where there is an island, but do not choose to do the "stop" part. Rule 30 is only advice.

This particular crossing has two small "islands", one in front of the other, holding street furniture, and a gap between them. The gap actually looks placed for pedestrians crossing, and as the islands have no dropped kerb, the gap is the route anyone with any sort of biggie would take, so in practice I am never crossing to the island and stopping.

Does any of this matter?

Drivers and pedestrians have to be careful, and the rules help them know what to expect. If they reach a different conclusion then that can, obviously, lead to an incident. So it is important that they both come to the same conclusion, that is why it matters. It also helps resolve who was "wrong" if there is an incident (which is no consolation if the pedestrian is squished). Both have to be very careful to avoid any squishing being involved. Understanding the rules clearly helps with that.

The good news is that the Highway Code is being changed to make it so you have to give way to someone "about to cross" the road (side road or zebra crossing). Once that change is in place the whole question of the island is moot, as someone on the island in the middle of a side road is clearly about to cross the "second half of the road" and so a car has to give way anyway, even if they consider somehow each side of the road to be a separate road for the purposes of rule 8 and 170.

Conclusion?

I had no idea that there would be a debate over the "island", or that there was any ambiguity or confusion over this. As above, it seemed clear to me, so interesting. This makes the changes that are coming to the rules a welcome clarification as it will cover giving way to someone waiting to cross even if they are on an island in the middle of the road.

Even now, before the change, motorists need to basically give way to anyone crossing a side road as if a zebra crossing was there - they already cope if crossing cars coming the other way - but the rules are changing to make this even clearer. Pedestrians are king when crossing a side road...

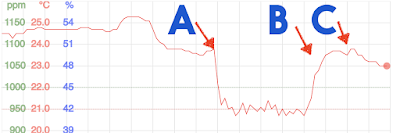

P.S. given the confusion caused by the "island", which is all pretty irrelevant, I wish I had started with this image, which also is a cause of problems on that junction.